Use of the electrochemical potential to characterise the surface damage behaviour of cyclically stressed materials

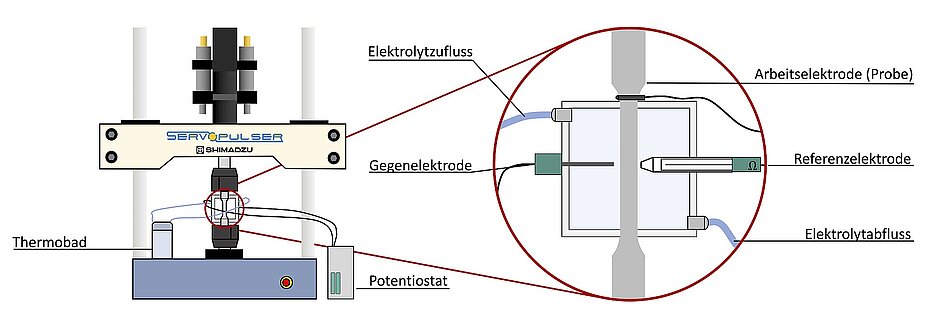

Within the scope of the research project, a corrosion measuring station is to be set up and integrated into a fatigue testing system so that electrochemical investigations can be carried out. By exposing the materials to various corrosive and non-corrosive media (e.g. distilled water, acids, etc.), the medium-material interface reaction can be recorded in terms of the corrosion potential and current. In further investigations, impedance measurements are also to be carried out as an additional source of information for the investigation of the processes at the interface. In the project phase applied for, the aspect of non-corrosive media on austenitic steels (X5CrNi1810) is to be considered first.

In the fatigue tests, the measuring length of the specimen is within a corrosion cell to be developed. If, due to the cyclic loading, intrusion and extrusion effects occur, followed by micro-crack formation on the surface, the oxide layers formed by the media contact crack and the corrosion current increases and the corrosion potential decreases. If the cracking stabilises, then re-passivation occurs, causing the corrosion current to drop and the corrosion potential to rise again to a stable value. Since surface damage is a continuously progressive process over the fatigue life, the degradation of the surface can be followed and reliably characterised with the electrochemical potential. By comparing the current-potential and impedance measurements with additive measurement techniques based on electrical resistance, temperature or magnetics, different damage mechanisms can be separated from each other, resulting in a clear gain in knowledge from a scientific and application perspective.